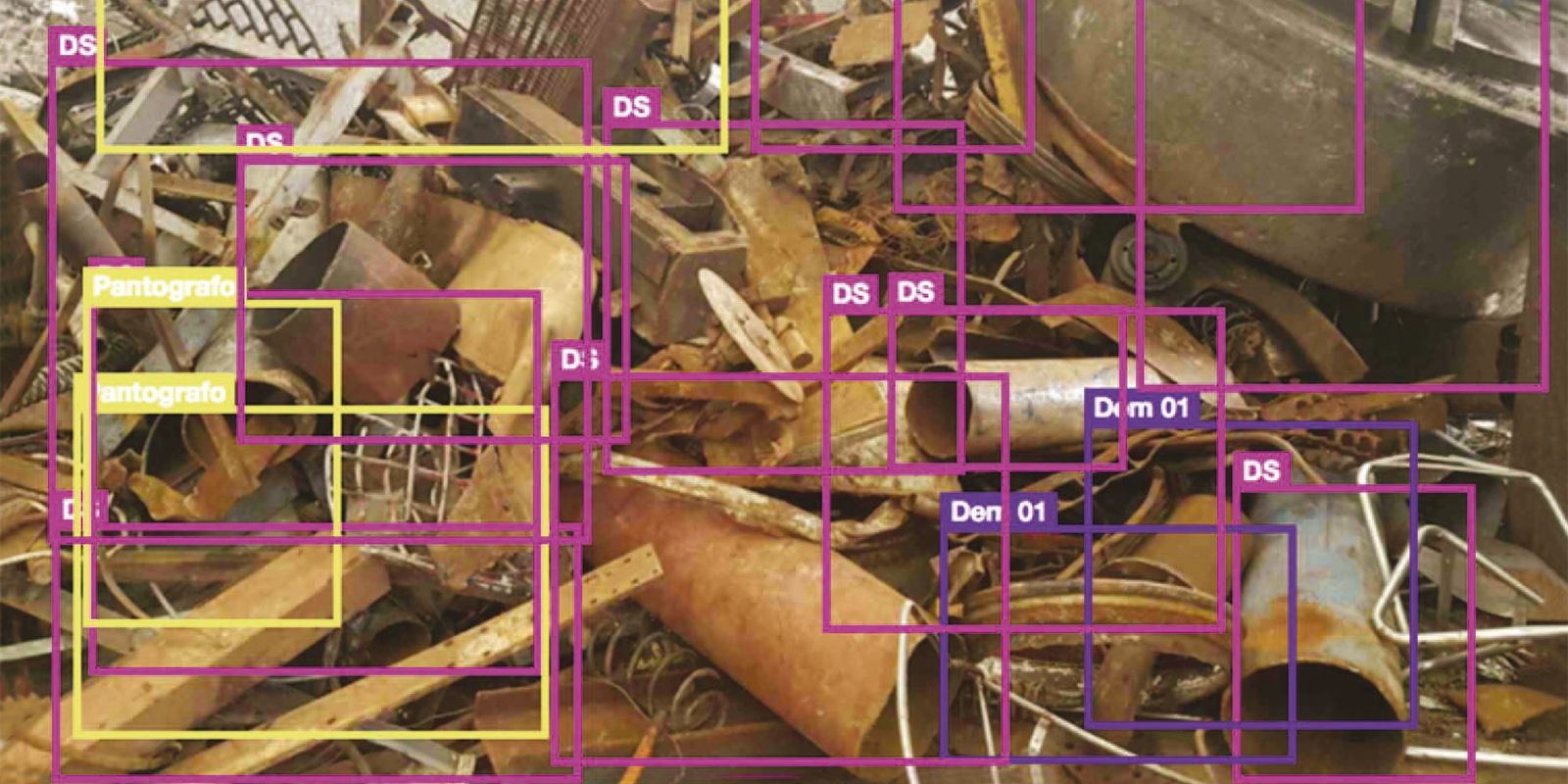

Tokyo Steel, the largest steel scrap consumer in Japan, purchases various types of scrap to feed its electric-arc furnace melting process. To support scrap handling and classification of the incoming material, the steelmaker selected Danieli Automation to supply the Q-ASC Automatic Scrap Classification system.

Q-ASC will go through various self-learning phases to achieve fully automatic scrap classification, providing real-time feedback for yard operations and objective support in claims made to suppliers.

The project will be implemented at the Kyushu plant but the cloud-based system architecture will make possible a seamless extension of Q-ASC to other Tokyo Steel plants.

The Q-ASC application, part of Danieli Automation DIGI&MET, is a response to EAF steelmakers’ need for Industry 4.0-compatible data technology.