Heavy beams and sheet piles producer EMSTEEL has selected Danieli technology and construction capability for the turnkey Thermo-Mechanical Control Process (TMCP) project at its rolling mill #4 in Abu Dhabi. EMSTEEL is the only producer of such heavy products in the MENA region.

Thanks to this investment EMSTEEL will expand its product portfolio with high-strength beams according to Grade 80 ASTM A913/A913M and S500ML EN 10025-4 (beam web depth up to 1036 mm, flange thickness up to 77 mm and linear weight of 634 kg/m).

High-strength beams are obtained by TMCP from low-alloy grades chemistry steels that provide excellent weldability while achieving good toughness at low temperatures.

The thermo-mechanical control process will be performed by Selective Flange Cooling (SFC) only, or in combination with Quenching & Self-Tempering (QST) treating the whole beam.

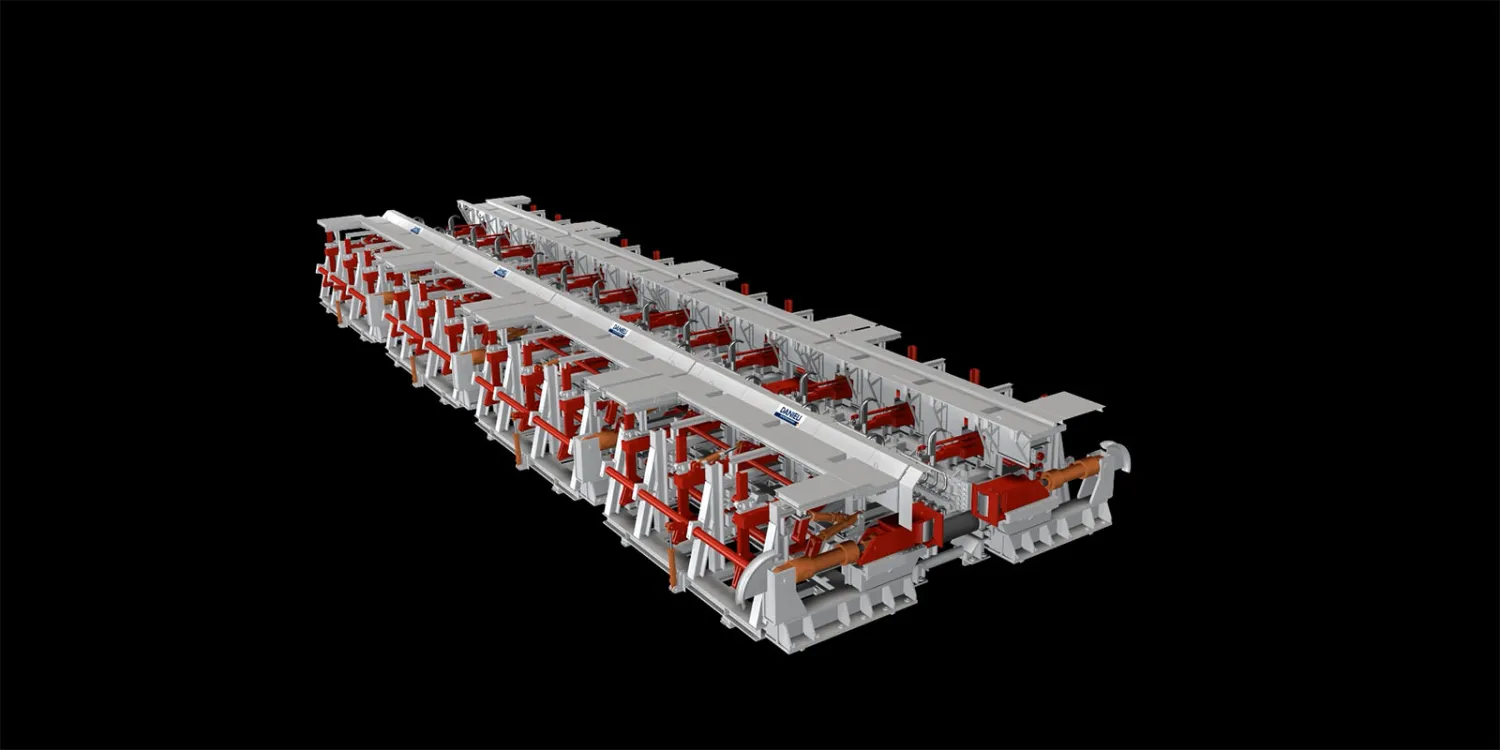

The SFC equipment will be installed at the entry and exit sides of the Ultra-Flexible Reversing (UFR) mill through cooling side guides, followed by QST system at the exit side.

Comprised of cooling banks and manifolds that surround the beam surfaces, Danieli QST features automatic positioning of the cooling manifolds according to the beam size.

Tests carried out at the Danieli Research Center demonstrated that the new Danieli QST package set to be installed at EMSTEEL rolling mill #4 will reduce water consumption by up to 30%.

Integrated in the rolling mill process control system and supplied by Danieli Automation, the new system for thermo-mechanical control, with dedicated PLC, HMI and TWS, will guarantee automatic process settings and controls.

Danieli Construction will carry out the entire execution of the site activities.

High-strength beams offer substantial savings in construction in terms of material weight and fabrication costs (mainly welding) for a wide range of applications, such as high-rise buildings, long-span bridges, seismic areas constructions and offshore structures.