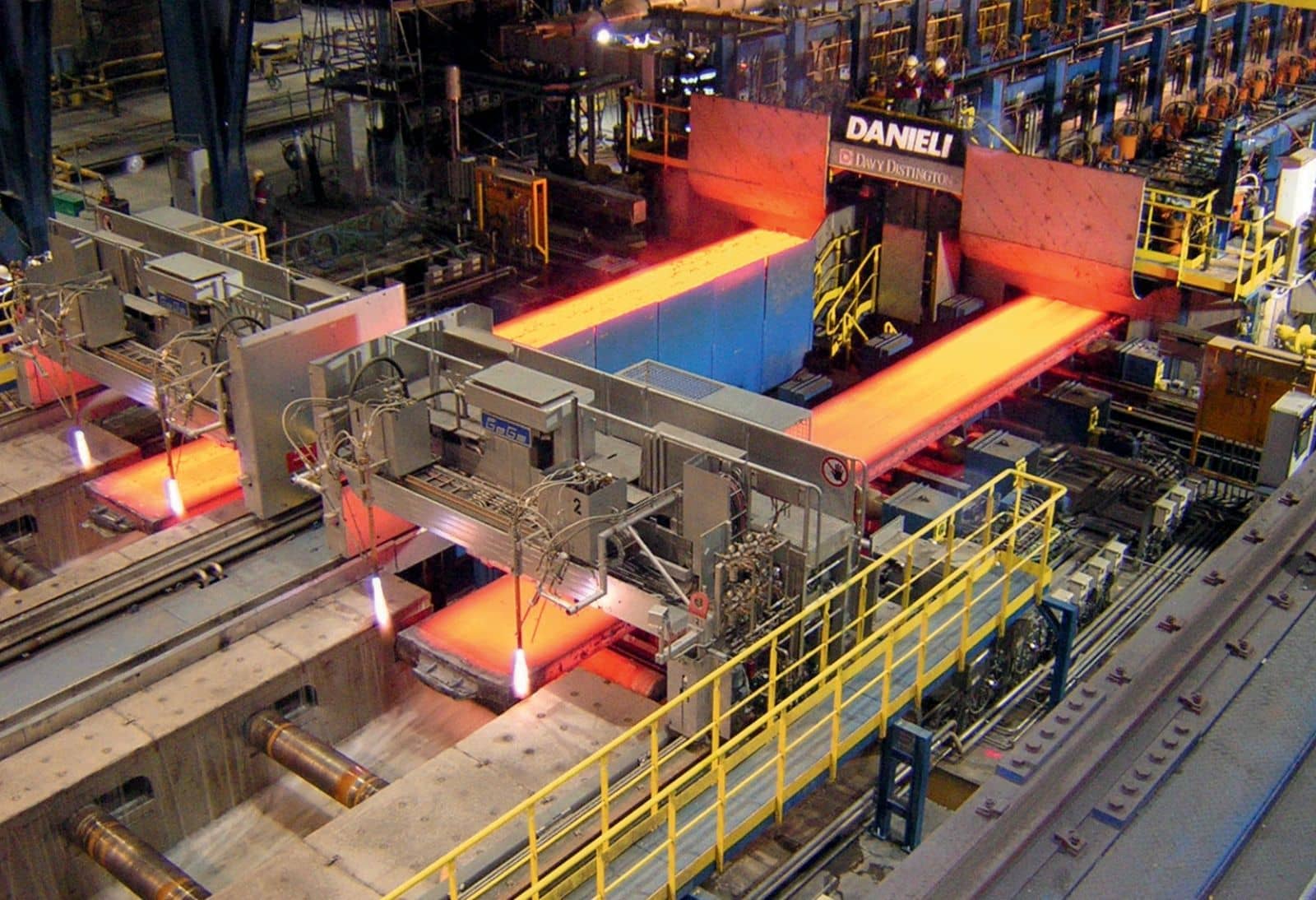

Arcelor Mittal Galaty has placed its trust in the technological packages and expertise in revamping projects of Danieli, for the quality upgrade of its 9.7-meter radius slab caster installed in Galati in 1978.

The installation of a new longer mould, an optimized secondary cooling on a new segment 0, and completely new Level 1 and Level 2 systems, supplied by Danieli Automation, will improve product quality by reducing slab defects like sliver, flakes and spider cracks for coils and plates.

The upgrade will be performed during a 21 day shutdown in September 2017.

In-classroom and on-site training will also be provided operator's personnel.

After the revamping the plant will produce 220-250-mm x 700-1900-mm slabs in low-carbon, peritectic, medium-carbon, micro alloyed, high-carbon and silicon steel grades.

Referring to ArcelorMittal Group, Danieli Davy Distington technologies for slab casters have been installed at Industeel and Sidmar in Belgium, Meizieres, Dunquerke and Fos-sur-Mer in France, Tubarão and Acesita in Brazil.

The Technological Packages included in Galati project are:

> Q-INMO hydraulic oscillator software;

> Q-LEVEL+ mould level control system with automated mould powder feeding;

> Q-MAP real time mould thermal monitoring system;

> Q-WIDTH in-line mould width and narrow face taper adjustment;

> Q-MIX tundish mix prediction system;

> Q-CUT slab cutting process optimization;

> Q-ART in-line slab quality assessment.

For further info:

Massimiliano Daita

m.daita@danieli.it

+39 0432 195 7635